Subtotal $0,00

Shopping cart

- Add: Room 2108, 21 / F, Hualin building,No 201 Hualin Road, Fuzhou, Fujian

- Tel: +86-0591-22578800

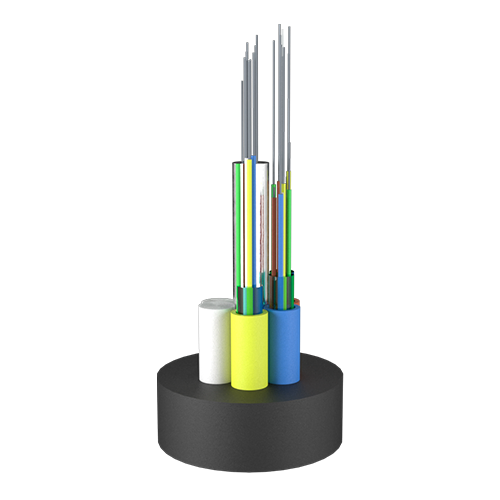

Figure 8 Cable| FAB-GYTC8A/S

The fibers, 250 µm, are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound.

Question? Click hereTechnical Informations & PricesCompartilhe:

The fibers, 250µm, are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound.

A steel wire locates in the center of core as a metallic strength member. The tubes (and fillers) are stranded around the strength member into a compact and circular cable core. After an Aluminum Polyethylene Laminate (APL) moisture barrier is applied around the cable core, this part of cable accompanied with the stranded wires as the supporting part are completed with a polyethylene (PE) sheath to be figure 8 structure Figure 8 cable DCTCBY, DCTCBS are also available on request.

This type of cable is specifically applied for self-suppo rting aerial installation.

Features

•High tensile strength of stranded wires meet the requirement of self-supporting and reduce installation cost

• Good mechanical and temperature performance

• High strength loose tube that is hydrolysis resistant

• Special tube filling compound ensure a critical protection of fiber

• The following measures are taken to ensure the cable watertight

• Steel wire used as the central strength member;

• Loose tube filling compound;

• 100% cable core filling;

• APL moisture barrier

Product Mechanical performance parameter

| Cable Code | Fiber Count |

Tubes | Fillers | Cable Diammeter (mm) |

Cable Weight Kg/ Km |

Tensile Strength (Long/Short term N) |

Crush Resistence (Long/Short term N/100mm) |

Bending Radius Dynamic / Static mm |

| FAB-GYTC8A/S-2-30 | 2-30 | 1-5 | 4 | 8.9×15.9 | 139/153 | 600/1500 | 300/1000 | 20D/10D |

| FAB-GYTC8A/S-32-36 | 32-36 | 6 | 0 | 9.2×16.2 | 147/162 | 600/1500 | 300/1000 | 20D/10D |

| FAB-GYTC8A/S-38-60 | 38-60 | 4-5 | 1-0 | 9.5×16.5 | 147/162 | 600/1500 | 300/1000 | 20D/10D |

| FAB-GYTC8A/S-62-72 | 62-72 | 6 | 0 | 10.0×17.0 | 163/179 | 600/1500 | 300/1000 | 20D/10D |

Transport/Storage/Operating Temperature: – 40°C~ + 70°C

The fibers, 250µm, are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound.

A steel wire locates in the center of core as a metallic strength member. The tubes (and fillers) are stranded around the strength member into a compact and circular cable core. After an Aluminum Polyethylene Laminate (APL) moisture barrier is applied around the cable core, this part of cable accompanied with the stranded wires as the supporting part are completed with a polyethylene (PE) sheath to be figure 8 structure Figure 8 cable DCTCBY, DCTCBS are also available on request.

This type of cable is specifically applied for self-suppo rting aerial installation.

Features

•High tensile strength of stranded wires meet the requirement of self-supporting and reduce installation cost

• Good mechanical and temperature performance

• High strength loose tube that is hydrolysis resistant

• Special tube filling compound ensure a critical protection of fiber

• The following measures are taken to ensure the cable watertight

• Steel wire used as the central strength member;

• Loose tube filling compound;

• 100% cable core filling;

• APL moisture barrier

Product Mechanical performance parameter

| Cable Code | Fiber Count |

Tubes | Fillers | Cable Diammeter (mm) |

Cable Weight Kg/ Km |

Tensile Strength (Long/Short term N) |

Crush Resistence (Long/Short term N/100mm) |

Bending Radius Dynamic / Static mm |

| FAB-GYTC8A/S-2-30 | 2-30 | 1-5 | 4 | 8.9×15.9 | 139/153 | 600/1500 | 300/1000 | 20D/10D |

| FAB-GYTC8A/S-32-36 | 32-36 | 6 | 0 | 9.2×16.2 | 147/162 | 600/1500 | 300/1000 | 20D/10D |

| FAB-GYTC8A/S-38-60 | 38-60 | 4-5 | 1-0 | 9.5×16.5 | 147/162 | 600/1500 | 300/1000 | 20D/10D |

| FAB-GYTC8A/S-62-72 | 62-72 | 6 | 0 | 10.0×17.0 | 163/179 | 600/1500 | 300/1000 | 20D/10D |

Transport/Storage/Operating Temperature: – 40°C~ + 70°C