Subtotal $0,00

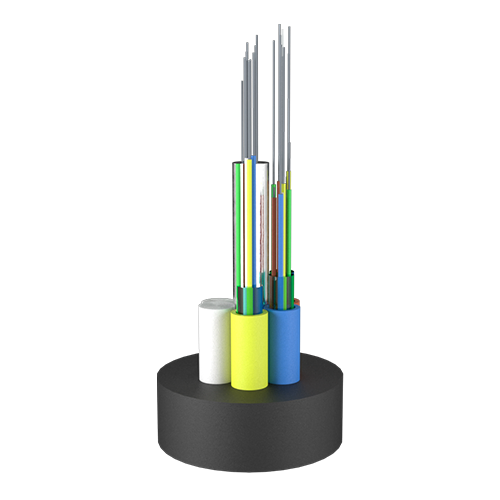

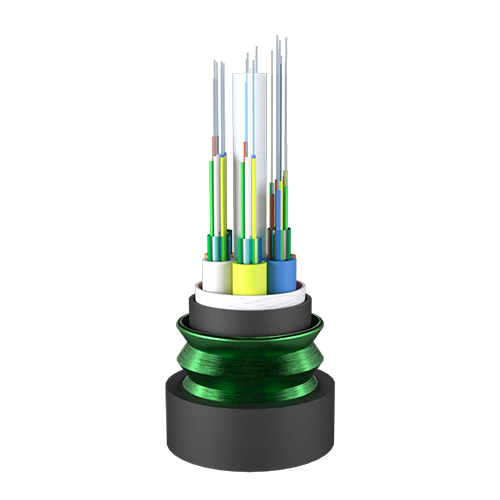

Stranded Loose Tube Non-metallic Strength Member Armored Cable | FAB-GYTY53

GYTY 53 optical cable is constructed by sheathing 250 um optical fiber into a loose tube made of high modulus material, and filling the loose tube with waterproof compound.

Question? Click hereTechnical Informations & PricesCompartilhe:

GYTY 53 optical cable is constructed by sheathing 250 um optical fiber into a loose tube made of high modulus material, and filling the loose tube with waterproof compound. The center of the cable core is a metal reinforcing core. For some optical cables with core numbers, a layer of polyethylene (PE) should be extruded outside the metal reinforced core. Loose sleeves (and fillers) are twisted around the central reinforcing core to form a compact and round cable core. The gap in the cable core is filled with water blocking filler.

The cable core is extruded with a layer of polyethylene inner sheath, and the double-sided plastic coated steel belt (PSP) is longitudinally coated and extruded with polyethylene sheath to form the cable.

Applicable: pipes, Overhead and directly buried

Features

•Good mechanical and temperature performance;

•High strength loose tube that is hydrolysis resistant; Special tube filling compound ensure a critical protection of fiber;

• Crush resistance and flexibility;

• The following measures are taken to ensure the cable watertight:

• Single Fiber Reinforced Plastic as the central strength member;

• Loose tube filling compound;

• 100% cable core filling

Product Mechanical performance parameter

| Cable Code | Fiber Count |

Tubes | Fillers | Cable Diammeter (mm) |

Cable Weight Kg/ Km |

Tensile Strength (Long/Short term N) |

Crush Resistence (Long/Short term N/100mm) |

Bending Radius Dynamic / Static mm |

| FAB-GYTY53-2-6 | 2-6 | 1 | 4 | 10.3 | 114 | 1000/3000 | 1000/3000 | 25D/12.5D |

| FAB-GYTY53-8-12 | 8-12 | 2 | 3 | 10.3 | 114 | 1000/3000 | 1000/3000 | 25D/12.5D |

| FAB-GYTY53-20-24 | 20-24 | 4 | 1 | 10.6 | 114 | 1000/3000 | 1000/3000 | 25D/12.5D |

| FAB-GYTY53-32-36 | 32-36 | 6 | 0 | 10.3 | 123 | 1000/3000 | 1000/3000 | 25D/12.5D |

| FAB-GYTY53-62-72 | 62-72 | 6 | 0 | 11.4 | 143 | 1000/3000 | 1000/3000 | 25D/12.5D |

| FAB-GYTY53-86-96 | 86-96 | 8 | 0 | 12.6 | 162 | 1000/3000 | 1000/3000 | 25D/12.5D |

| FAB-GYTY53-134-144 | 134-144 | 12 | 0 | 15.2 | 225 | 1000/3000 | 1000/3000 | 25D/12.5D |

Transport/Storage/Operating Temperature: – 40°C~ + 70°C

STANDARDS

Reference with standard YD/T 901-2009 as well as IEC 60794-1

GYTY 53 optical cable is constructed by sheathing 250 um optical fiber into a loose tube made of high modulus material, and filling the loose tube with waterproof compound. The center of the cable core is a metal reinforcing core. For some optical cables with core numbers, a layer of polyethylene (PE) should be extruded outside the metal reinforced core. Loose sleeves (and fillers) are twisted around the central reinforcing core to form a compact and round cable core. The gap in the cable core is filled with water blocking filler.

The cable core is extruded with a layer of polyethylene inner sheath, and the double-sided plastic coated steel belt (PSP) is longitudinally coated and extruded with polyethylene sheath to form the cable.

Applicable: pipes, Overhead and directly buried

Features

•Good mechanical and temperature performance;

•High strength loose tube that is hydrolysis resistant; Special tube filling compound ensure a critical protection of fiber;

• Crush resistance and flexibility;

• The following measures are taken to ensure the cable watertight:

• Single Fiber Reinforced Plastic as the central strength member;

• Loose tube filling compound;

• 100% cable core filling

Product Mechanical performance parameter

| Cable Code | Fiber Count |

Tubes | Fillers | Cable Diammeter (mm) |

Cable Weight Kg/ Km |

Tensile Strength (Long/Short term N) |

Crush Resistence (Long/Short term N/100mm) |

Bending Radius Dynamic / Static mm |

| FAB-GYTY53-2-6 | 2-6 | 1 | 4 | 10.3 | 114 | 1000/3000 | 1000/3000 | 25D/12.5D |

| FAB-GYTY53-8-12 | 8-12 | 2 | 3 | 10.3 | 114 | 1000/3000 | 1000/3000 | 25D/12.5D |

| FAB-GYTY53-20-24 | 20-24 | 4 | 1 | 10.6 | 114 | 1000/3000 | 1000/3000 | 25D/12.5D |

| FAB-GYTY53-32-36 | 32-36 | 6 | 0 | 10.3 | 123 | 1000/3000 | 1000/3000 | 25D/12.5D |

| FAB-GYTY53-62-72 | 62-72 | 6 | 0 | 11.4 | 143 | 1000/3000 | 1000/3000 | 25D/12.5D |

| FAB-GYTY53-86-96 | 86-96 | 8 | 0 | 12.6 | 162 | 1000/3000 | 1000/3000 | 25D/12.5D |

| FAB-GYTY53-134-144 | 134-144 | 12 | 0 | 15.2 | 225 | 1000/3000 | 1000/3000 | 25D/12.5D |

Transport/Storage/Operating Temperature: – 40°C~ + 70°C

STANDARDS

Reference with standard YD/T 901-2009 as well as IEC 60794-1