Subtotal $0,00

Fire Resistant Cable| FAB-GJFZV58

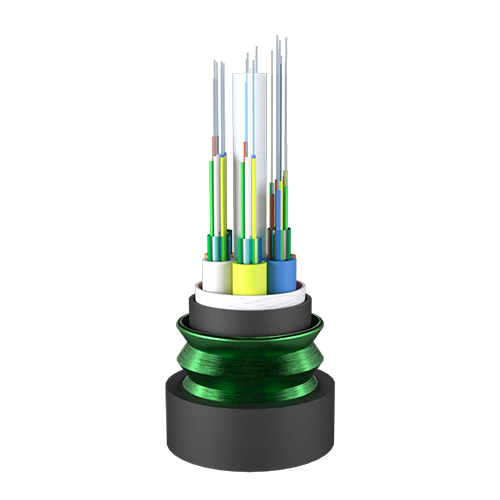

The fibers, 250 µm, are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound.

Question? Click hereTechnical Informations & PricesCompartilhe:

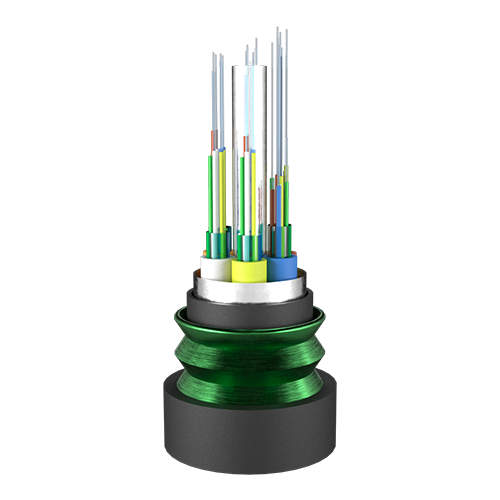

The fibres, 250 µm, are positioned in a loose tube made of a high modulus plastic.The tubes are filled with a water-resistant fillling compound. A Fibre Reinforced Plastic (FRR) locates in the center of core as a non-metallic strength member. The tubes (and fillers) are stranded around the strength member into a compact and circular core. Then the cable core is covered with an inner flame-retardant sheath. After a corrugated steel tape armor is applied, the cable is completed with a outer flame-retardant sheath.

Features

• Good mechanical, temperature performance and fire resistant property

• High strength loose tube that is hydrolysis resistant;

• Special tube filling compound ensure a critical protection of fiber;

• Good crush resistance and flexibility;

• The following measures are taken to ensure the cable watertight;

• Crush resistance and flexibility;

• Single Fiber Reinforced Plastic as the central strength member;

• Loose tube filling compound;

Product Mechanical performance parameter

| Cable Code | Cable Diammeter (mm) |

Cable Weight Kg/Km |

Tensile Strength (Long/Short term N) |

Crush Resistence (Long/Short term N/100mm) |

Bending Radius Dynamic / Static mm |

| FAB-GJFZY58-6-30 | 10.3 ± 0.5 | 194 | 400/1000 | 1000/3000 | 25D/12.5D |

| FAB-GJFZY58-32-36 | 10.6 ± 0.5 | 203 | 400/1000 | 1000/3000 | 25D/12.5D |

| FAB-GJFZY58-44-60 | 10.9 ± 0.5 | 205 | 400/1000 | 1000/3000 | 25D/12.5D |

| FAB-GJFZY58-62- 72 | 11.4 ± 0.5 | 243 | 400/1000 | 1000/3000 | 25D/12.5D |

| FAB-GJFZY58-74-96 | 12.6 ± 0.5 | 282 | 400/1000 | 1000/3000 | 25D/12.5D |

Transport/Storage/Operating Temperature: – 20°C~ + 60°C | Installation Temperature: – 5°C- + 50°C

APPLICATIONS

• lndoor distribution;

• lnterconnect from outdoor to indoor for optical cable distribution equipment;

STANDARDS

Reference with standard YD/T 1258.4-2005, ICEA-596,GR-409, IEC60794, IEC60331-25-1999, etc.

The fibres, 250 µm, are positioned in a loose tube made of a high modulus plastic.The tubes are filled with a water-resistant fillling compound. A Fibre Reinforced Plastic (FRR) locates in the center of core as a non-metallic strength member. The tubes (and fillers) are stranded around the strength member into a compact and circular core. Then the cable core is covered with an inner flame-retardant sheath. After a corrugated steel tape armor is applied, the cable is completed with a outer flame-retardant sheath.

Features

• Good mechanical, temperature performance and fire resistant property

• High strength loose tube that is hydrolysis resistant;

• Special tube filling compound ensure a critical protection of fiber;

• Good crush resistance and flexibility;

• The following measures are taken to ensure the cable watertight;

• Crush resistance and flexibility;

• Single Fiber Reinforced Plastic as the central strength member;

• Loose tube filling compound;

Product Mechanical performance parameter

| Cable Code | Cable Diammeter (mm) |

Cable Weight Kg/Km |

Tensile Strength (Long/Short term N) |

Crush Resistence (Long/Short term N/100mm) |

Bending Radius Dynamic / Static mm |

| FAB-GJFZY58-6-30 | 10.3 ± 0.5 | 194 | 400/1000 | 1000/3000 | 25D/12.5D |

| FAB-GJFZY58-32-36 | 10.6 ± 0.5 | 203 | 400/1000 | 1000/3000 | 25D/12.5D |

| FAB-GJFZY58-44-60 | 10.9 ± 0.5 | 205 | 400/1000 | 1000/3000 | 25D/12.5D |

| FAB-GJFZY58-62- 72 | 11.4 ± 0.5 | 243 | 400/1000 | 1000/3000 | 25D/12.5D |

| FAB-GJFZY58-74-96 | 12.6 ± 0.5 | 282 | 400/1000 | 1000/3000 | 25D/12.5D |

Transport/Storage/Operating Temperature: – 20°C~ + 60°C | Installation Temperature: – 5°C- + 50°C

APPLICATIONS

• lndoor distribution;

• lnterconnect from outdoor to indoor for optical cable distribution equipment;

STANDARDS

Reference with standard YD/T 1258.4-2005, ICEA-596,GR-409, IEC60794, IEC60331-25-1999, etc.