Subtotal $0,00

Shopping cart

- Add: Room 2108, 21 / F, Hualin building,No 201 Hualin Road, Fuzhou, Fujian

- Tel: +86-0591-22578800

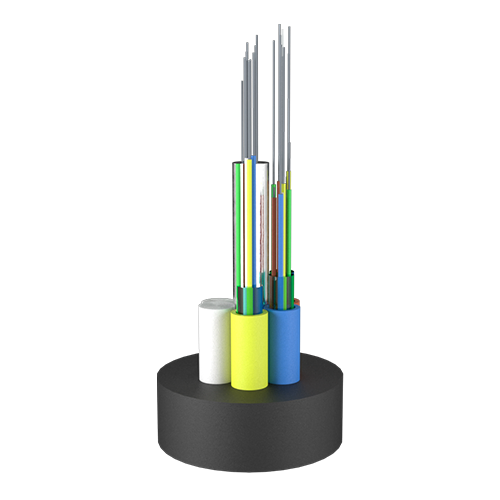

Stranded Loose Tube Non-metallic Strength Member Non-armored Cable | FAB-GYFTY

The fibers,250 µ m, are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound.

Question? Click hereTechnical Informations & PricesCompartilhe:

DESCRIPTION

The fibers,250 µ m, are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound. A Fiber Reinforced Plastic (FRP) locates in the center of core as a non-metallic strength member. The tubes (and fillers) are stranded around the strength member into a compact and circular core. After the cable core is filled with the fillling compound to protect it from water ingress. the cable is completed with a PE sheath.

Application: Duct/Aerial

CHARACTERISTICS

• Good mechanical and temperature performance;

• High strength loose tube that is hydrolysis resistant;

• Special tube filling compound ensure a critical protection of fiber;

• Crush resistance and flexibility;

• PE sheath protects cable form ultraviolet radiation;

• The following measures are taken to ensure the cable watertight;

• Single Fiber Reinforced Plastic as the central strength member;

• Loose tube filling compound;

• 100% cable core filling;

STANDARDS

Reference with Standard YD/T 901-2009 as well as IEC 60794-1

TECHNICAL PARAMETERS

| Cable Code | Fiber Count |

Tubes | Fillers | Cable Diammeter (mm) |

Cable Weight Kg/ Km |

Tensile Strength (Long/Short term N) |

Crush Resistence (Long/Short term N/100mm) |

Bending Radius Dynamic / Static mm |

| FAB-GYFTY/S-2-6 | 2-6 | 1 | 4 | 8.3 | 59 | 600/1500 | 300/1000 | 20D/10D |

| FAB-GYFTY/S-8-12 | 8-12 | 2 | 3 | 8.3 | 59 | 600/1500 | 300/1000 | 20D/10D |

| FAB-GYFTY/S-20-24 | 20-24 | 4 | 1 | 8.3 | 59 | 600/1500 | 300/1000 | 20D/10D |

| FAB-GYFTY/S-38-48 | 38-48 | 4 | 1 | 8.3 | 67 | 600/1500 | 300/1000 | 20D/10D |

| FAB-GYFTY/S-62-72 | 62-72 | 6 | 0 | 9.0 | 67 | 600/1500 | 300/1000 | 20D/10D |

| FAB-GYFTY/S-86-96 | 86-96 | 8 | 0 | 10.2 | 82 | 600/1500 | 300/1000 | 20D/10D |

| FAB-GYFTY/S-134-144 | 134-144 | 12 | 0 | 12.8 | 125 | 600/1500 | 300/1000 | 20D/10D |

Transport/Storage/Operating Temperature: – 20°C~ + 60°C

DESCRIPTION

The fibers,250 µ m, are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound. A Fiber Reinforced Plastic (FRP) locates in the center of core as a non-metallic strength member. The tubes (and fillers) are stranded around the strength member into a compact and circular core. After the cable core is filled with the fillling compound to protect it from water ingress. the cable is completed with a PE sheath.

Application: Duct/Aerial

CHARACTERISTICS

• Good mechanical and temperature performance;

• High strength loose tube that is hydrolysis resistant;

• Special tube filling compound ensure a critical protection of fiber;

• Crush resistance and flexibility;

• PE sheath protects cable form ultraviolet radiation;

• The following measures are taken to ensure the cable watertight;

• Single Fiber Reinforced Plastic as the central strength member;

• Loose tube filling compound;

• 100% cable core filling;

STANDARDS

Reference with Standard YD/T 901-2009 as well as IEC 60794-1

TECHNICAL PARAMETERS

| Cable Code | Fiber Count |

Tubes | Fillers | Cable Diammeter (mm) |

Cable Weight Kg/ Km |

Tensile Strength (Long/Short term N) |

Crush Resistence (Long/Short term N/100mm) |

Bending Radius Dynamic / Static mm |

| FAB-GYFTY/S-2-6 | 2-6 | 1 | 4 | 8.3 | 59 | 600/1500 | 300/1000 | 20D/10D |

| FAB-GYFTY/S-8-12 | 8-12 | 2 | 3 | 8.3 | 59 | 600/1500 | 300/1000 | 20D/10D |

| FAB-GYFTY/S-20-24 | 20-24 | 4 | 1 | 8.3 | 59 | 600/1500 | 300/1000 | 20D/10D |

| FAB-GYFTY/S-38-48 | 38-48 | 4 | 1 | 8.3 | 67 | 600/1500 | 300/1000 | 20D/10D |

| FAB-GYFTY/S-62-72 | 62-72 | 6 | 0 | 9.0 | 67 | 600/1500 | 300/1000 | 20D/10D |

| FAB-GYFTY/S-86-96 | 86-96 | 8 | 0 | 10.2 | 82 | 600/1500 | 300/1000 | 20D/10D |

| FAB-GYFTY/S-134-144 | 134-144 | 12 | 0 | 12.8 | 125 | 600/1500 | 300/1000 | 20D/10D |

Transport/Storage/Operating Temperature: – 20°C~ + 60°C